5G wireless communication is key to the advancement of industrial automation (Industry 4.0), opening up entirely new possibilities. However, frequently, especially in factories, the corresponding application is extremely sensitive to poor communication performance, e.g. non-deterministic timing behavior, potentially causing significant production equipment downtime. The successful roll-out of 5G in these scenarios will therefore require the advance stress testing of wireless communication performance under realistic conditions (see also Unified Approach for the Assessment of Industrial Wireless Solutions [1])

The goal of the [performance testing] is to verify compliance with the values required for the application to operate reliably in the specified use case – and, additionally, to determine the communication system’s entire performance range (its maximum and minimum values).

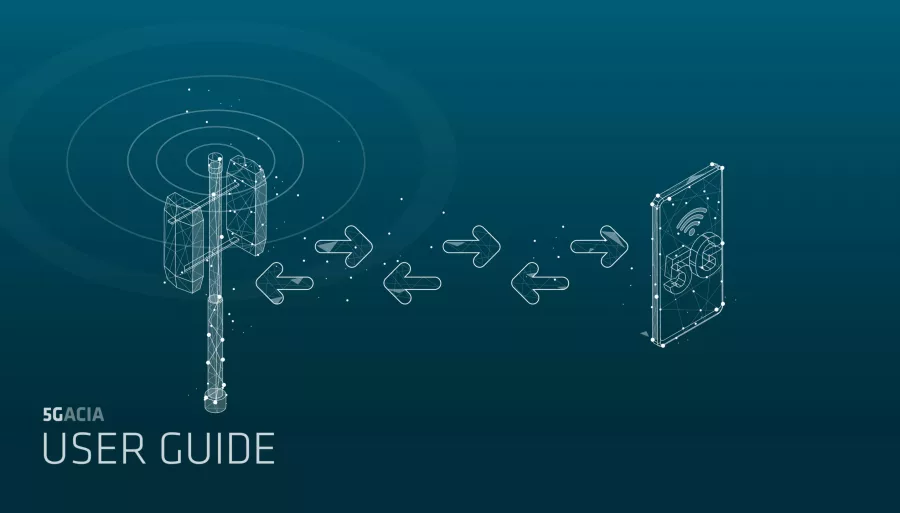

Performance testing involves two different sets of parameters: performance and baseline parameters. They are described in greater detail in the subtopic “Performance Testing Parameters”.

It is also important to know how to properly test the performance of a 5G system. This is outlined in the subtopic “How to Test Performance Parameters”.

A universal concept for performance testing system is presented in the subtopic “Universal Performance Testing System Concept”.

Examples of round-trip device testing and network testing, including standardized test methods, are provided in the subtopic “Examples of Round-Trip Performance Testing for Devices and Networks”, as well as examples for one-way logical link testing in the subtopic “Examples of One-Way Logical Link Performance Testing”.

This topic is based on information from the 5G ACIA white paper “Performance Testing of 5G Systems for Industrial Automation”.

[1] L. Rauchhaupt, M. Krätzig, U. Meier and P. Neufeld, “A unified approach for the assessment of industrial wireless solutions,” IEEE 16th International Conference on Emerging Technologies and Factory Automation (ETFA), 2011.