For core use cases

Making Industrial 5G happen

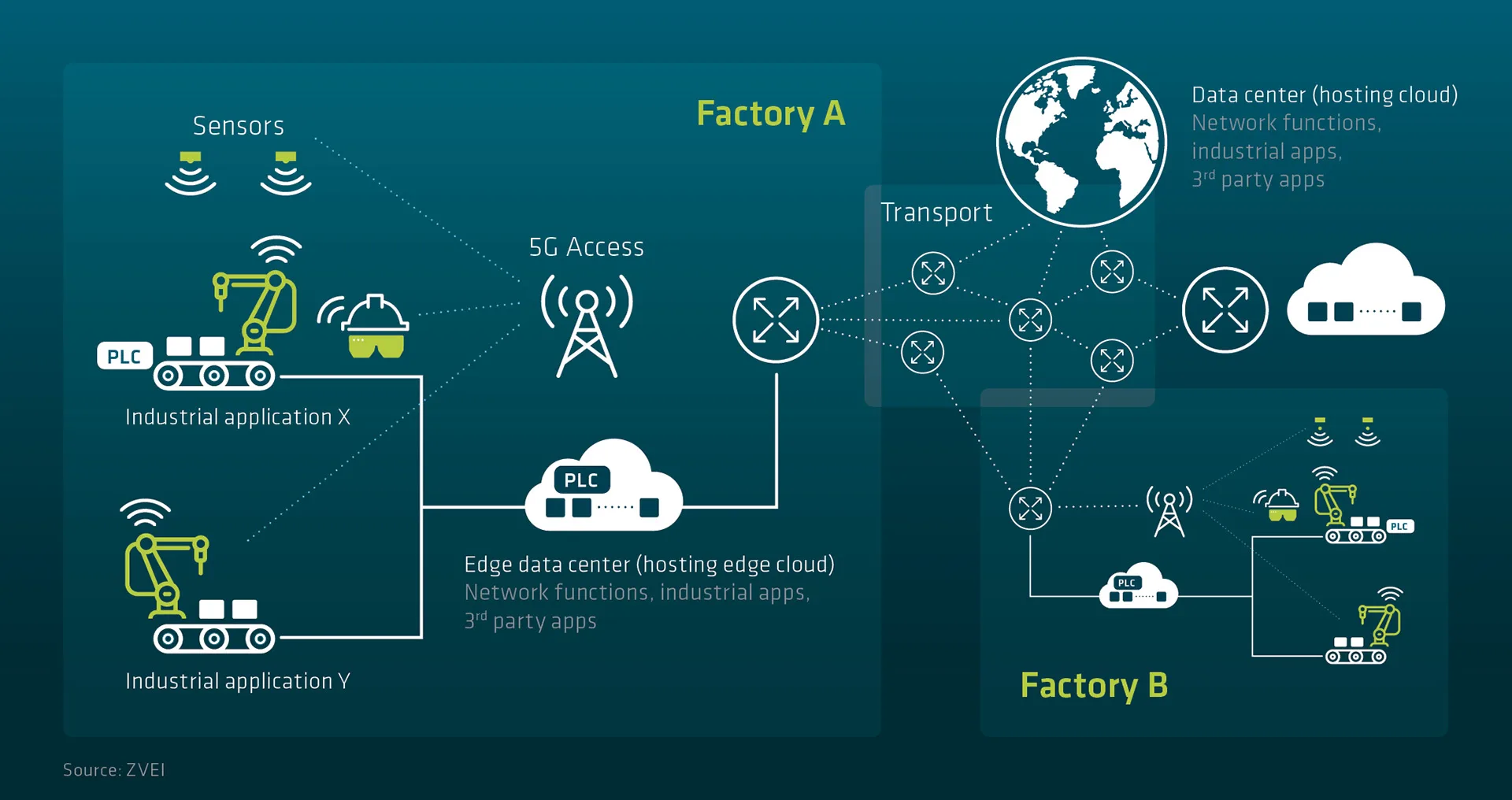

5G has the potential to provide (wireless) connectivity for a wide range of different use cases and applications in industry. In the long-term, it may actually lead to convergence of the many different communication technologies that are in use today, thus significantly reducing the number of relevant industrial connectivity solutions. Just as there is an ongoing trend towards Time-Sensitive Networking (TSN) for established (wired) Industrial Ethernet solutions, 5G is likely to become the standard wireless technology of choice, as it may for the first time enable direct and seamless wireless communication from the field level to the cloud.

Next era in industrial production known as “Industry 4.0”

Manufacturing is diverse and heterogeneous, and is characterized by a large number of automation use cases. These can be divided into five distinct areas of application, as depicted below:

- Factory automation,

- Process automation,

- Human-machine interfaces (HMIs) and production IT,

- Logistics and warehousing, and

- Monitoring and predictive maintenance