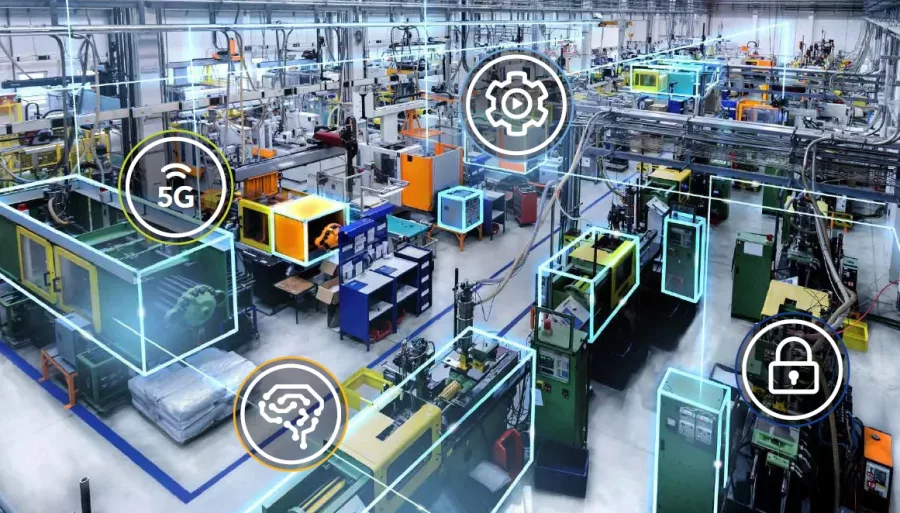

In the factory, the system is being tested to track raw material assets used and containers of components. The two main aims were to improve the visibility of inventory and match data from the factory’s systems more accurately to the actual flow of assets in the factory. The latter has historically been out of sync, which has led to unscheduled downtime of production lines.

With the 5G-A system, Haier achieved continuous coverage in the test areas, totally 8,000 square meters; has improved inventory tracking from less than 95% accuracy to 99.99%; and is achieving positioning accuracy of less than 10 meters in 90% of instances, making it much easier to find items.

The testbed will push to deploy 5G-A pRRUs and 100 ambient IoT tags in different zones of Haier washing machine factory, and verify functions of periodic inventory, inventory by instruction, E2E tracing