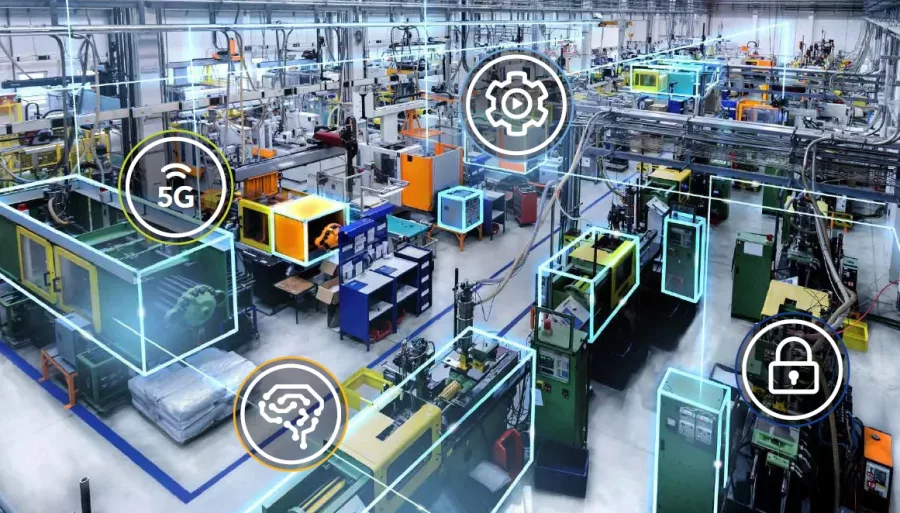

The AAU/UNIOVI/NOKIA/FESTO Zero Touch Production Testbed in the AAU 5G Smart Production Lab will demonstrate a 5G-based fully-automated production environment – without humans. By integrating and coordinating the operation of stationary manufacturing modules and mobile robotic elements, a safer and more secure production environment will be possible, allowing to reshape the production schemes by allocating humans to other (new) tasks, potentially increasing the production output. The testbed integrates FESTO stationary production modules and programmable logic controllers (PLCs) with autonomous mobile robots (AMRs) equipped with robotic manipulators which further use HD video cameras as sensors to steer their automated operations (zero touch production manipulators). All control flows are reliably operated over a NOKIA/AAU 5G SA/NSA network with FR1 (3.7 GHz), FR2 (26 GHz) and edge-cloud capabilities.

The testbed will investigate the optimal operational performance from both a communication and a production perspective via validation, performance, and inter-operability testing. This testbed strengthens the collaboration between academic, OT and ICT members in building and demonstrating practical industrial solutions, aiming at disseminating the results and gained experience with the 5G-ACIA international community to facilitate global adoption of 5G for Industry.