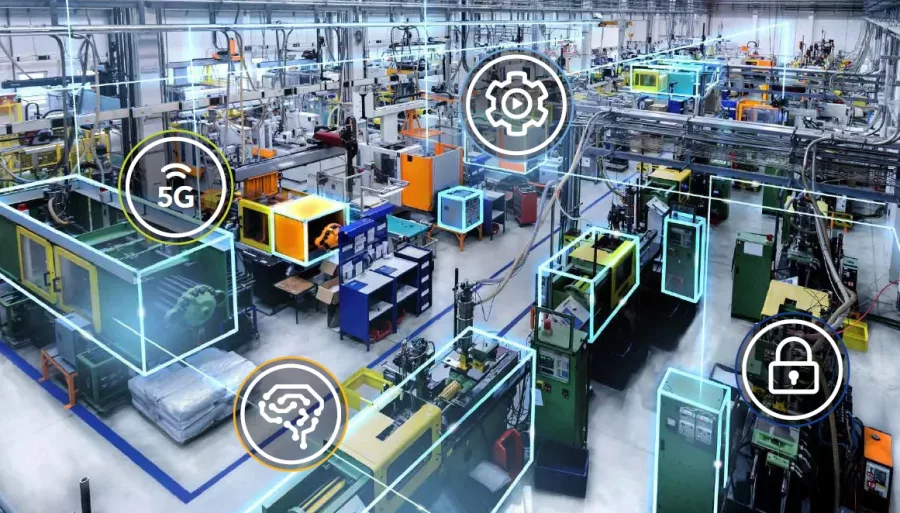

The testbed features a standalone, non-public, indoor 5G network deployment covering an industrial manufacturing hall of 8000 m. The objective of the testbed is to demonstrate how 5G empowers factory automation and intralogistics in a real production environment. This will be achieved through developing and trialing use cases such as 5G-enabled cloud-controlled automated guided vehicles (AGVs) and industrial Ethernet over 5G on the factory floor.

The following testbed results will be delivered to the 5G-ACIA

- A description of the testbed setup, deployment and configuration -A description of the realized use cases together with a list of their requirements and benefits

- Results of the validity and performance of the two use cases. This will include the general validation of the feasibility of the use cases and an investigation of interactions of application performance and 5G network. The 5G network performance will be provided in KPIs like throughput and latency