5G sidelink, in the form standardized by the Third Generation Partnership Project (3GPP) Release 16, is a feature of the 5G system that enables devices to communicate directly with one another without necessitating the need to route user data via the cellular infrastructure. Its use is growing in importance, especially in the commercial, public safety, and automotive (V2X) domains. 5G sidelink communication may be used in different constellations with respect to radio cover- age such as in-coverage, partial coverage, or out-of-coverage.

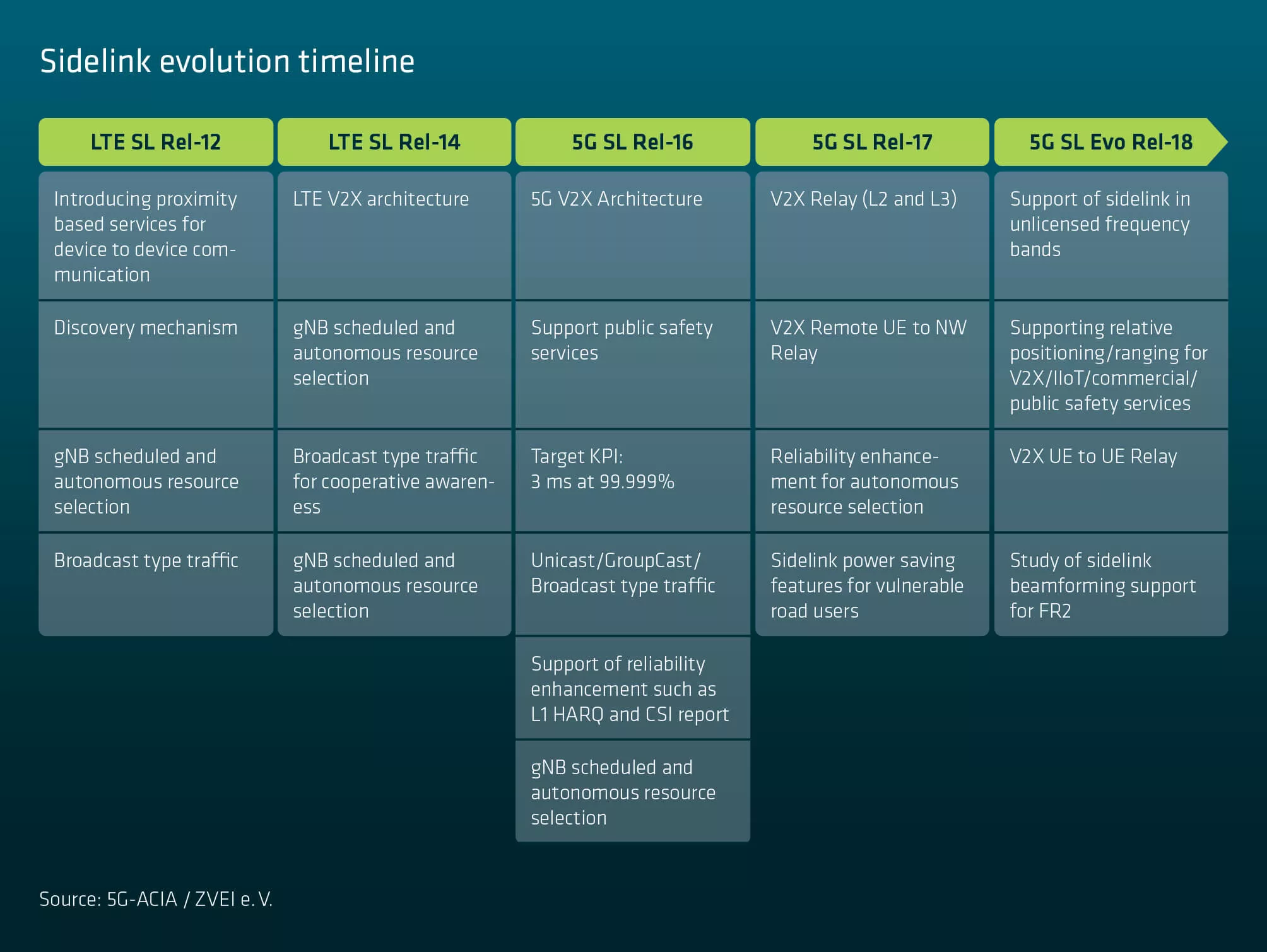

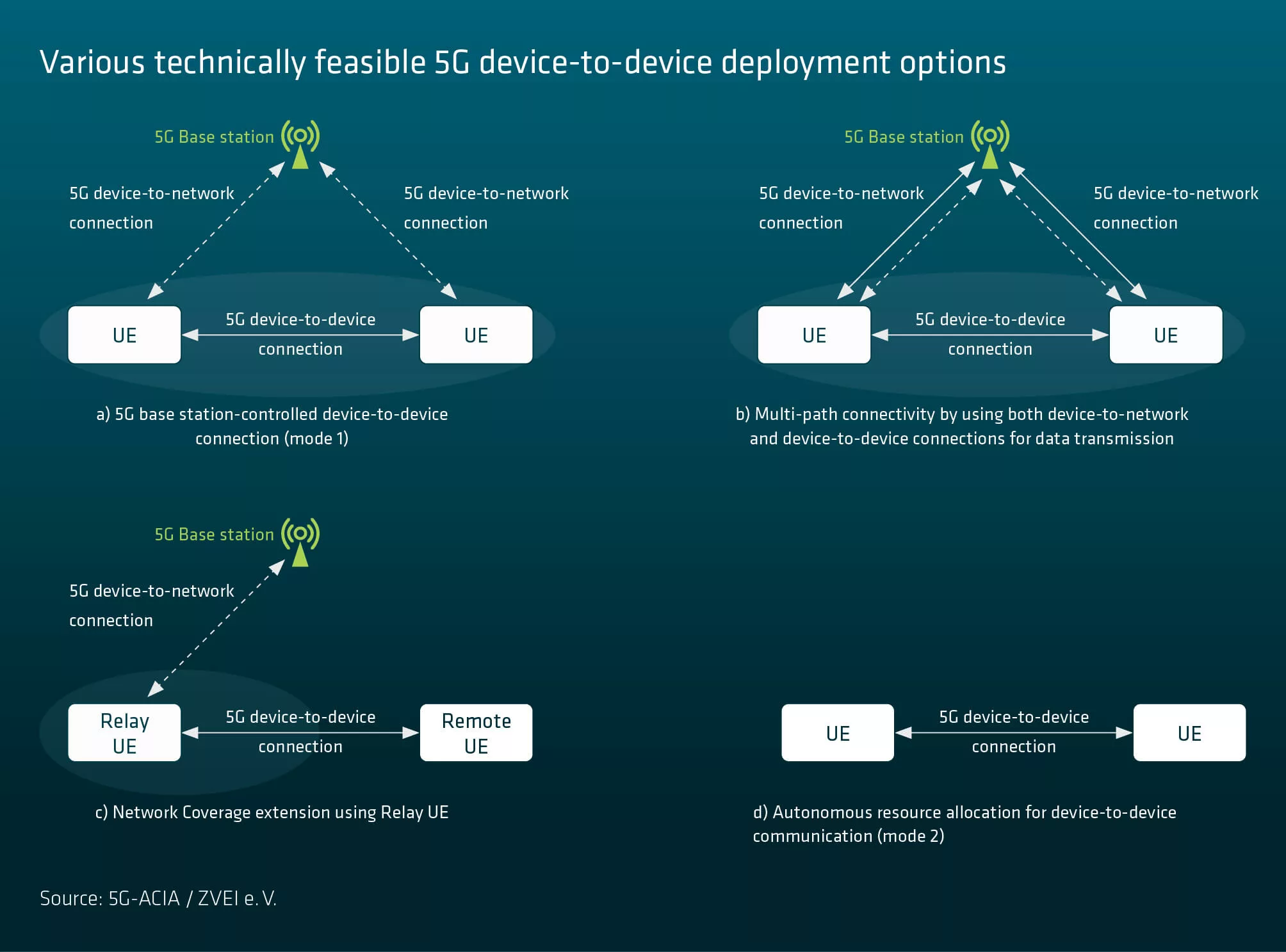

The technology supports two main operating modes. In one, referred to as mode 1, a base station activates sidelink resources with configured grants for periodic traffic or dynamic grants for aperiodic traffic. In the other (mode 2), a mobile device (UE) autonomously uses sensing mechanisms to monitor control channel information from nearby UEs and select sidelink resources for transmitting it. 3GPP recently approved 5G Advanced study items for investigating the unlicensed use of 5G sidelink [4] and 5G sidelink positioning [5] for meet- ing the requirements of commercial, public safety, IIoT, and vehicle-to-everything (V2X) use cases.

Reliable, deterministic communication is vital for factory applications that use 5G. 3GPP’s releases 16 and 17 already specified requirements for the most typical use cases, namely motion control and cooperative carrying mobile robots. Since then, it has added specifications for network-centric solutions with stringent reliability and latency to meet the needs of factory and other applications. The standard solutions now available from 3GPP are expected to meet the communication requirements of these use cases, provided that the 5G network is properly deployed and has good coverage.

Wireless communication via the 5G network is scheduled by gNB, by doing so the exact latency requirements are expected to be met based on proper deployment. Due to the various responsibility models and actors involved in 5G network deployment, chances exist that the intended service area does not always benefit from full 5G network coverage. 5G sidelink could be a tool to extend coverage to those areas.

Not enough attention has yet been paid to analyzing the performance of 5G sidelink communication in factory use cases. For example, low latency and high reliability requirements (specified in 3GPP TS 22.104 [3]) must be met to support industrial factory and process applications. These requirements can be even more stringent than those for V2X, which needs a latency of 3 ms and 99.999% reliability (see Table 5.3-1 of 3GPP TS 22.186 [6]). To address these shortfalls and appropriately enhance 5G sidelink for industrial factory applications, it will be necessary for 5G sidelink to support new QoS capabilities and time-sensitive communication, among other things, in future 3GPP releases.

This chapter discusses the potential benefits and challenges of using 5G sidelink communication in automated factories.

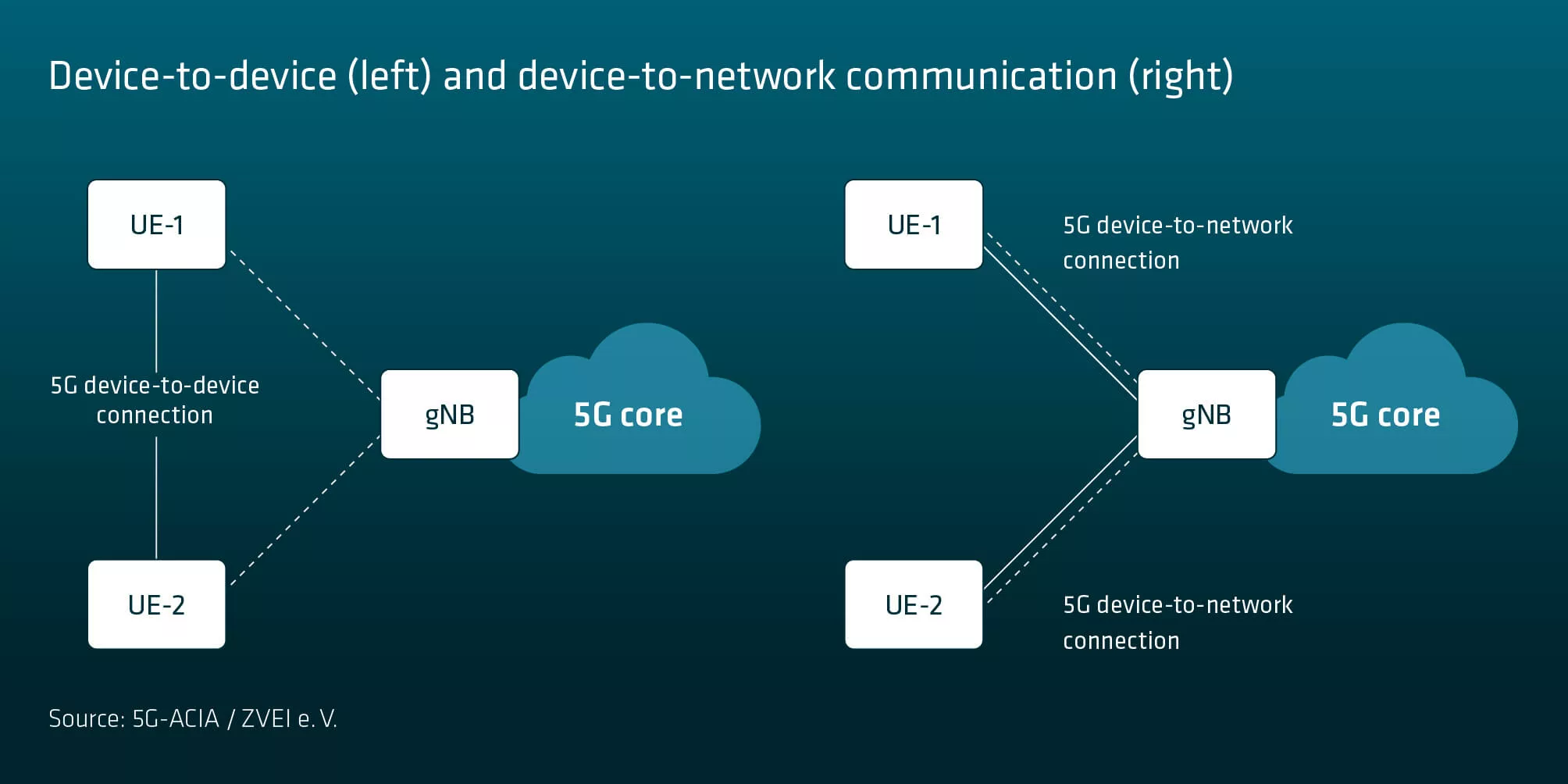

5G sidelink makes it possible to directly send user data be- tween devices (via the NR-PC5 interface) instead of routing it via the base station (gNB), which requires it to pass through the NR-Uu interface twice (see Figure 2).

5G sidelink communication could possibly be used in Indus- trial IoT when devices are in proximity to one another. UEs of these kinds, such as mobile robots in the cooperative carrying use case, typically maintain a line of sight with little or no relative motion (see section 4.2). For user data transmission between devices, the single wireless hops of 5G sidelink communication (NR-PC5) could deliver benefits in the form of reduced latency because there is only one wireless hop in- stead of two via the network. The extent to which latency is reduced with 5G sidelink communication depends on the distance between UEs, among other factors.

5G sidelink as defined in Release 16 includes in-coverage, partial coverage, and out-of-coverage modes. So the possible scenarios for deploying 5G sidelink in factory environments include the following:

d) Network relay for coverage extension, in which 5G sidelink connectivity between devices helps the base station reach UEs that are outside the area covered by the network.

d) Autonomous resource allocation mode (mode 2):

5G sidelink devices communicate without the support of a base station, and sidelink resources are autonomously selected from a (pre-) configured resource pool by a transmitter UE (e. g., using a sensing mechanism).

While 5G sidelink communication is technically possible in all deployment scenarios, the choice of selecting the 5G sidelink deployment in a factory environment is up to the factory network operator. The network operator is required to under- stand when sidelink might be a suitable solution, i. e., wheth- er 5G sidelink can achieve the performance requirements of the use case and whether the particular deployment fits with the conditions of that use case. The factor affecting the 5G sidelink deployment may include whether 5G sidelink meets the QoS requirements in relation to latency and reliability (which requires further evaluation) and potentially spectrum availability for 5G sidelink.

The following use cases, described in 3GPP TS 22.104 [3], were investigated in connection with deploying 5G sidelink for factory automation.

Motion Control

A motion control system controls moving and/or rotating parts of machines in a well-defined manner, for example in printing presses, machine tools, or packaging machines. In these scenarios, it may not be feasible to use a wired connection to a gateway device (containing one or more field devices) in the rotating part of a robot arm.

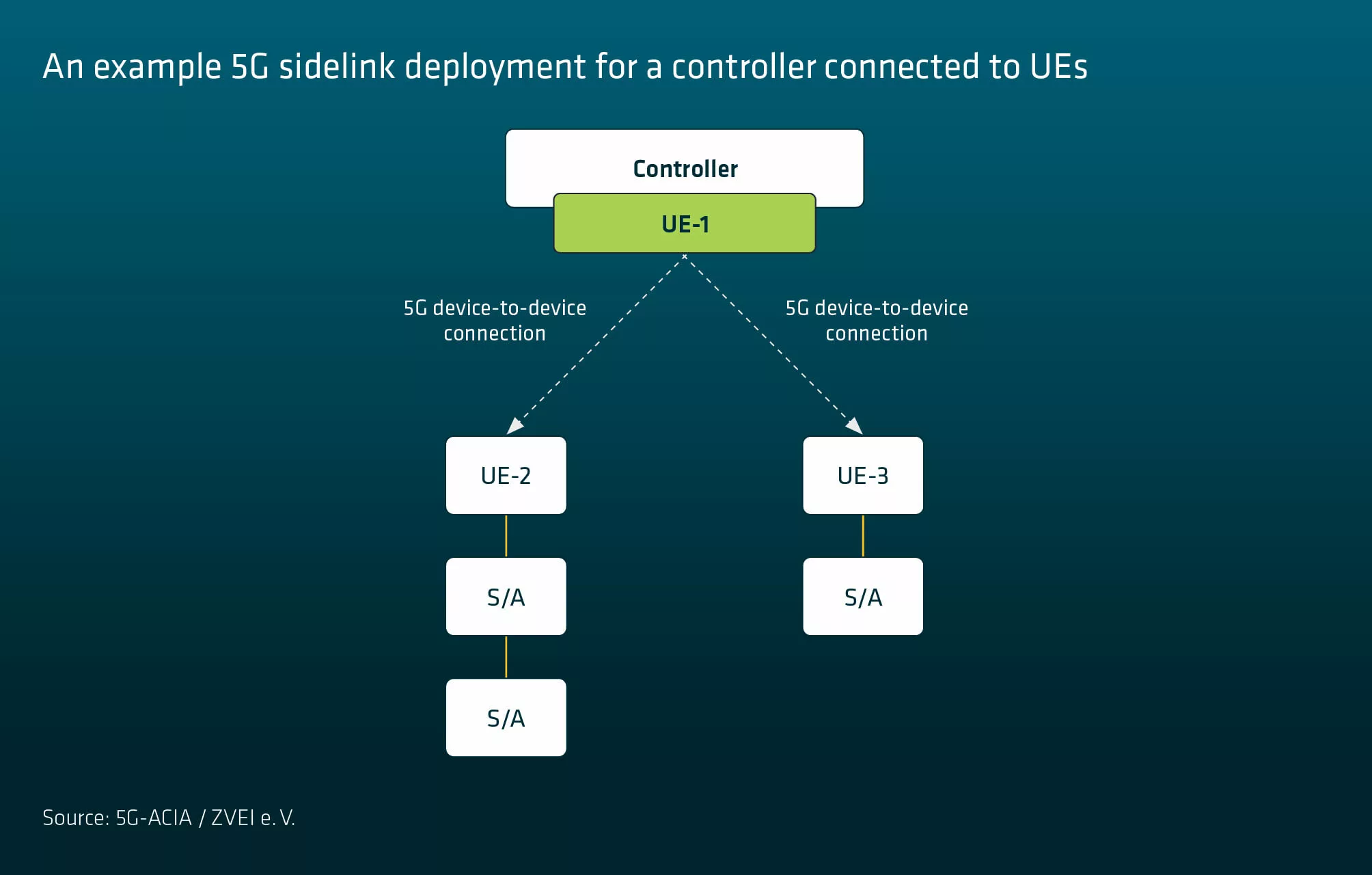

5G sidelink connectivity between a motion controller connected to a UE and one or more actuators may reduce communication latency or resource consumption compared to adevice-to-network connection, assuming that the same level of radio link reliability is achievable in both cases.

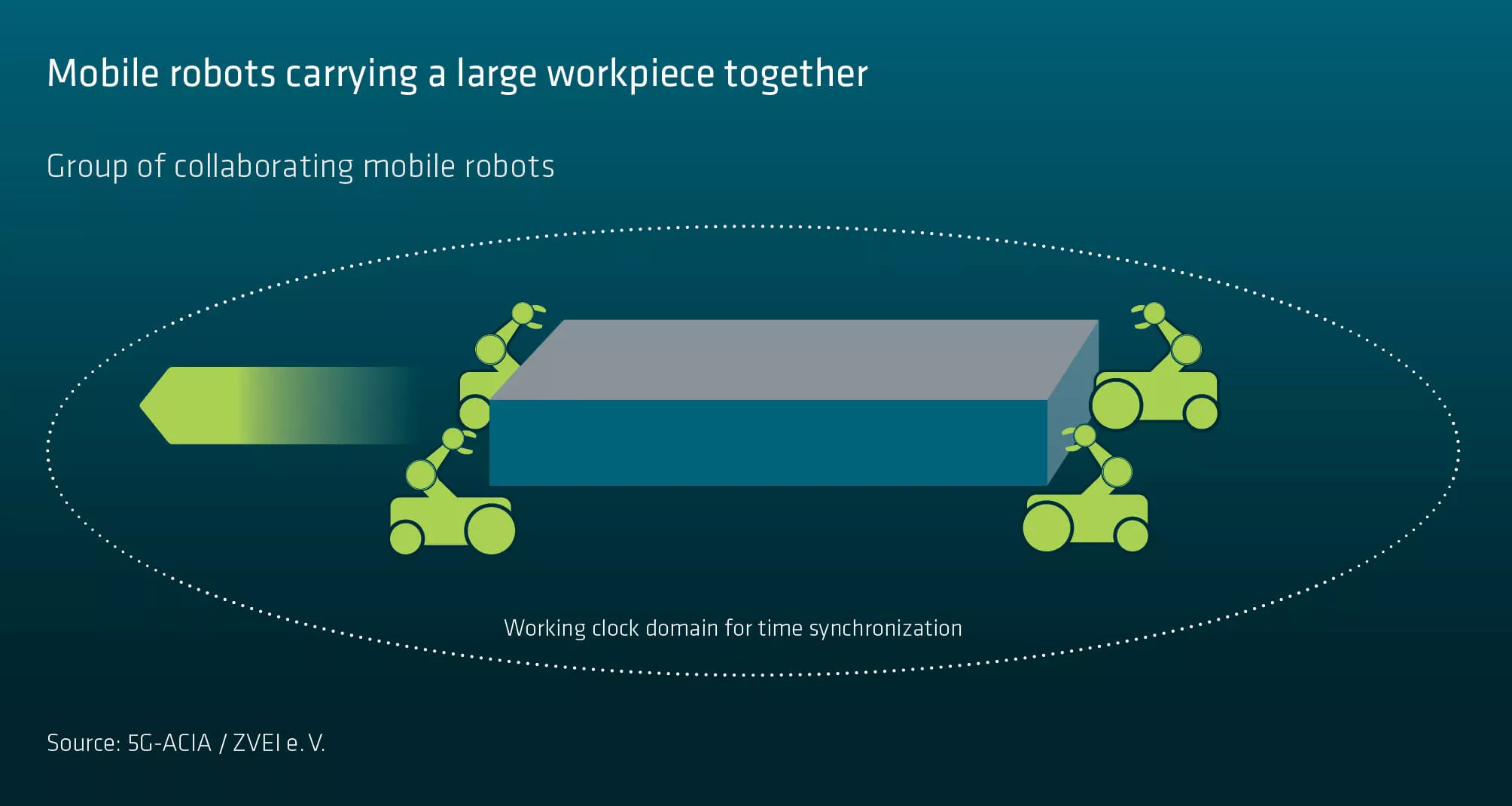

In a smart factory, a group of mobile robots or AGVs can collaborate as a team to carry large, heavy, fragile workpieces across the factory floor (see Figure 4). The control application achieves this cooperation by controlling their drives and motions. 5G sidelink is suited for maintaining stable wireless connections among collaborating mobile robots or AGVs that are fairly close together.

Mobile robots/AGVs integrate a 5G UE for 5G sidelink communication. The automation application on the collaborating mobile robots/AGVs establishes 5G sidelink communication. When the mobile robots are gathered around the workpiece, they form a collaborating group using basic information on things like group formation, a 5G radio configuration, and a working clock domain for time synchronization and deterministic communication. The simplest implementation of this use case for lifting and moving heavy but fragile workpieces is two AGVs in virtual coupling mode with the required KPIs of synchronicity and periodic deterministic communication.

In this white paper we have investigated the following use cases: motion controller, controller-to-controller, cooperative carrying robots, and relative positioning. 5G sidelink communication for close-proximity applications is attractive for factory deployment and may yield significant benefits. However, challenges and limitations have also been identified in connection with the availability, reliability, and range of 5G sidelink.

The principal requirements – based on those of the use cases described in this white paper – are ultrareliable, low-latency communication, precise clock synchronization, periodic deterministic time-sensitive communication, and support for 5G sidelink communication in nonpublic networks.

The 5G sidelink standardization efforts up to and including Release 17 mainly focused on meeting the latency and reliability requirements of public safety and automotive use cases, which are less demanding than factory use cases. URLLC requirements are not supported by current 5G NR sidelink specifications.

This white paper also concludes that 5G sidelink communication is supported better when implemented in private networks (SNPN, PNI-NPN). Factory network operators can deploy it according to their own preferences.

Feasibility studies of 5G sidelink factory applications for future 3GPP releases will need to evaluate performance (for example, the upper limit of low latency and the achievable reliability across defined distances), possibly by considering 5G URLLC features to understand the potential benefits of 5G sidelink-URLLC and time-sensitive communication.

Do you want to learn more about this future-oriented topic? Please download or share the 5G-ACIA white paper as a PDF file.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information