Despite the growing technical maturity of 5G, many manufacturing companies remain hesitant to adopt the technology due to uncertainty about its economic and operational value. This whitepaper addresses this gap by presenting an estimation-based evaluation method that helps assess the business benefits of 5G deployments in industrial environments.

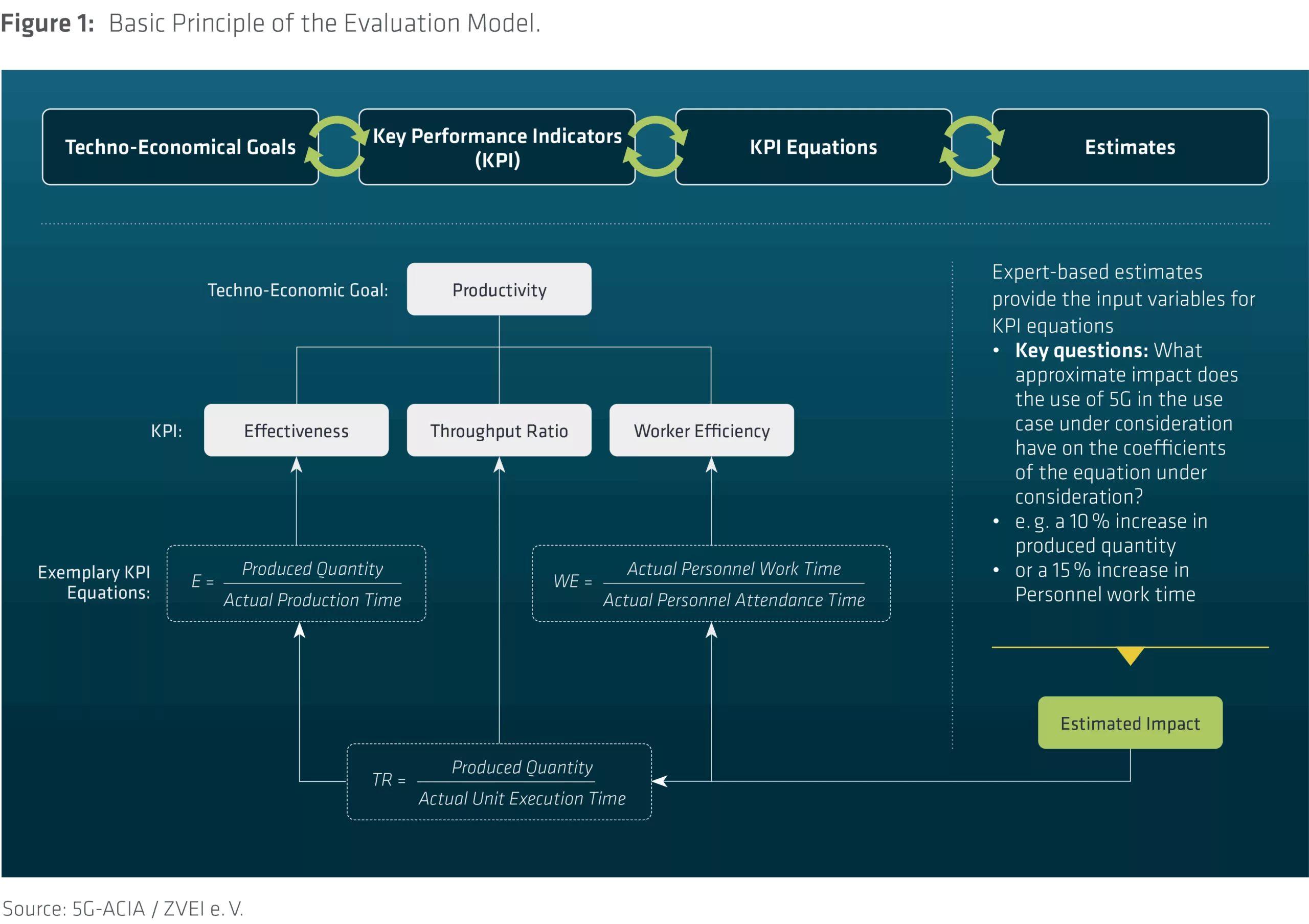

The methodology integrates techno-economic goals (such as productivity, mobility, and safety), KPI equations, and expert estimates to quantify the impact of 5G compared to legacy technologies. The approach is illustrated using three practical use cases: an AGV use case, a milling use case, and an automated valet parking in automotive manufacturing use case.

By applying this framework, industrial stakeholders can objectively estimate the return on investment and operational gains from adopting 5G. This supports informed decision-making and accelerates the digital transformation of production systems. Furthermore, it helps solution providers like mobile network operators and vendors and their respective sales teams to carefully assess the price level.

The document summarized a robust method to estimate the business value of 5G across diverse industrial applications. The methodology was validated through three use cases:

It compared 5G with legacy technologies (e.g., 4G and Ethernet) and showed measurable benefits in productivity, mobility, safety, and sustainability. Looking ahead, the methodology offers a foundation for further development:

The whitepaper encourages organizations to leverage this approach to drive their own 5G investment analyses and accelerate the digital transformation of manufacturing.

Do you want to learn more about this future-oriented topic? Please download or share the 5G-ACIA white paper as a PDF file.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information