This white paper provides an overview of the kinds of devices that can be needed in order for 5G to benefit the manufacturing industry and related sectors. As 5G systems are implemented in factories and other settings, attention is increasingly shifting to designing devices that will let them work on the shop floor. A whole new generation of 5G-compatible devices is now being developed. This paper provides an introduction and practical guide to this field for everyone who is directly or indirectly involved in it, whether they are academics, manufacturers, factory owners or operators, designers, or engineers. Its main purpose is to provide an easy-to-read overview of the various categories of devices and solutions that are now appearing, while going into greater technical detail on key technical topics and design issues.

The main types of 5G devices are presented and described and a number of real-world examples discussed while describing the most important technical issues, challenges, and solutions involved in each case. On a more theoretical level, reference architectures are then presented for the most common types of industrial 5G devices, including generic block diagrams.

Finally, various aspects of the physical architecture of such devices are discussed, covering challenges such as explosion protection, storage of credentials, the pros and cons of chipset versus module solutions, radio module form factor standards, a comparison of standalone and integrated application processors, and implementation of interfaces.

The design of industrial 5G devices requires skills from several different engineering disciplines. Some aspects which influence the design choices include:

When designing industrial 5G devices, it is essential to take these and many other aspects into account.

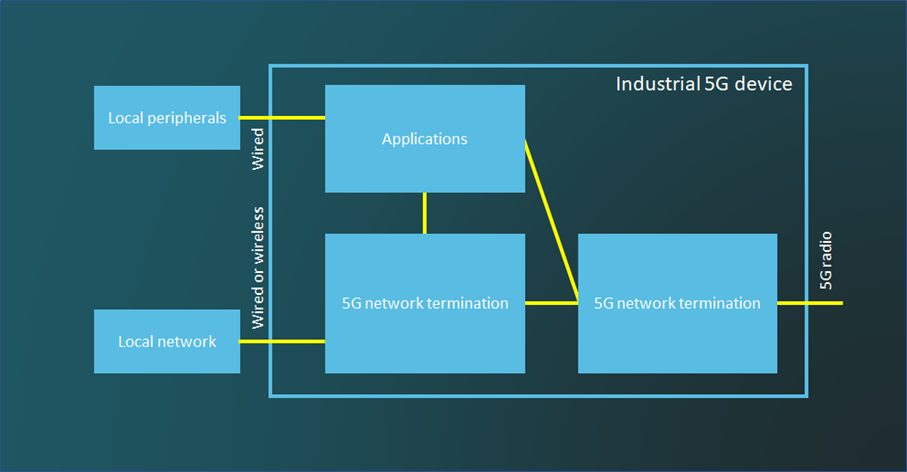

As shown in the figure above, an industrial 5G device has a 5G radio interface for communicating with local peripherals or a local network. The local peripherals are typically sensors and actuators, while the local network will typically be industrial Ethernet or fieldbus.

From a logical perspective, an industrial 5G device comprises a 5G network termination, a local network termination, and application functionality. It also includes configuration and management functions (not shown in the figure above).

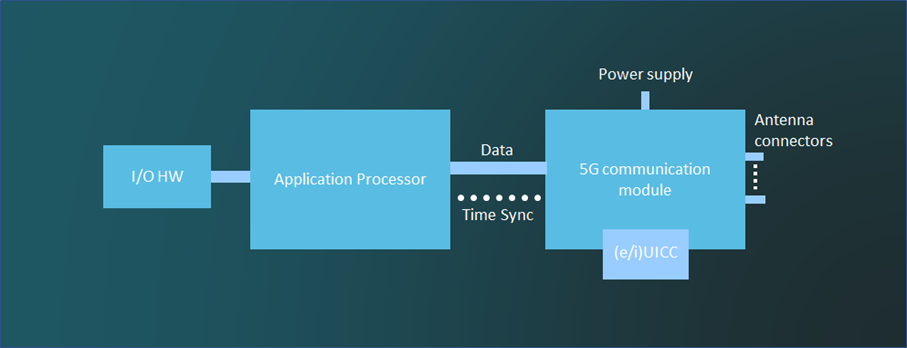

In physical terms, an industrial 5G device generally comprises a radio module and an application processor as shown above. There are multiple options for designing the physical interface between the application processor and radio module. Which is most appropriate in a given case depends on data throughput, latency, and time synchronization requirements.

There are also other options for designing the physical architecture. One is to use individual chips instead of a radio module. Although this approach has some advantages, it typically requires a greater development and certification effort. Another is to integrate the application processor in the radio module. Although this reduces the number of components, fewer development environments are available than for a standalone application processor.

In this white paper, we have discussed the architectural choices for industrial 5G devices. They depend on several criteria, including:

In the white paper, we introduce a new functional entity called an EAP identity function (EIF). The EIF holds the credentials needed for EAP authentication plus other relevant information that is otherwise stored in the USIM.

The white paper also addresses the use of the GSMA standardized remote SIM provisioning (RSP) standard. From a technical perspective, the remote SIM provisioning standards may meet the need for provisioning operator credentials in a private network setting. However, the ecosystem for the remote SIM provisioning standards has been optimized for public operators. It would be beneficial to adopt the remote SIM provisioning ecosystem to also meet the needs of private networks.

Do you want to learn more about this future-oriented topic? Please download or share the 5G-ACIA white paper as a PDF file.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information