Performance testing is key to building trust in a 5G system fulfilling the industrial application’s requirements. It is the basis to analyse a 5G system’s behaviour prior or simultaneously to its deployment in a real-world operative use case. This white paper seeks to show how (stress) performance testing can be achieved. It explains that aspects to be aware of and what to consider when preparing and conducting performance tests from the industrial application’s point of view. Baseline parameters to be described and performance parameters to be measured are defined. The interfacing of testing system and system under test is examined by discussing the reference interface. A universal performance testing concept is presented. Additionally, 5G-ACIA’s testbed endorsement and how these testbeds are aiming to conduct performance tests is shown.

This white paper explains what aspects to be aware of and what to consider when preparing and conducting performance tests.

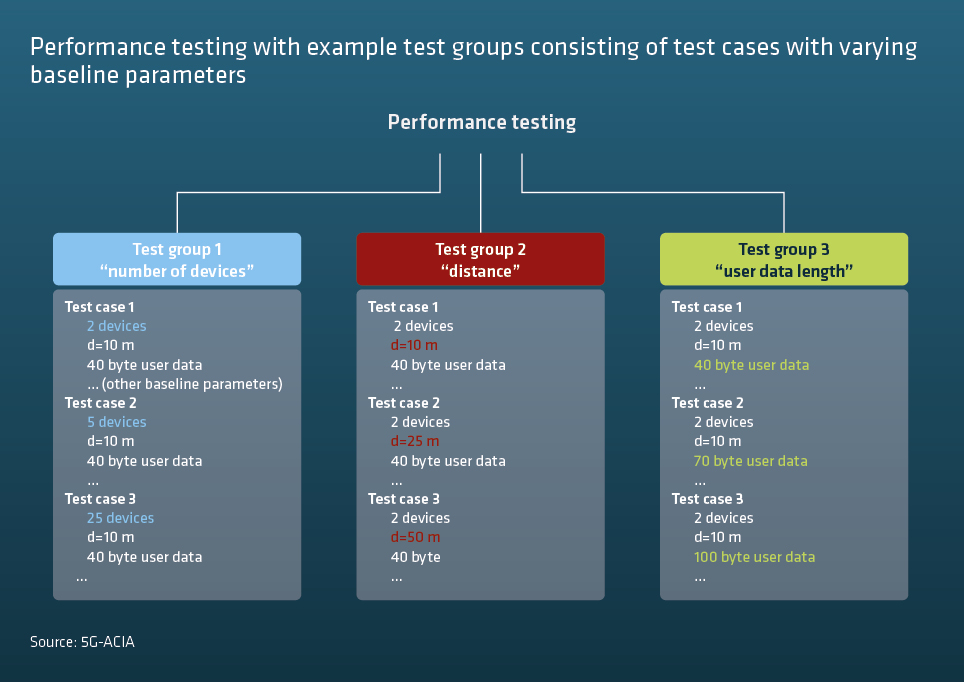

Performance tests are organized in test groups consisting of multiple test cases. Each test group aims to investigate a certain feature and thus answer a certain question on the system’s performance. All baseline parameters have to be described carefully for each test case. By this, the measured performance parameters are reproducible and comparable.

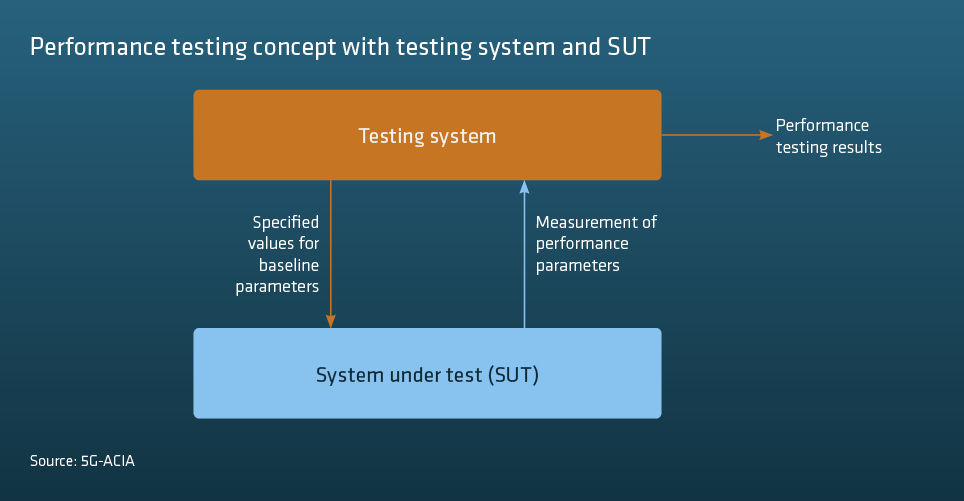

During performance tests, the testing system controls the system under test by reproducibly providing the values for the baseline parameters as specified in the test cases. The testing system observes the system under test’s behaviour by measuring its performance parameters based on which the performance is evaluated.

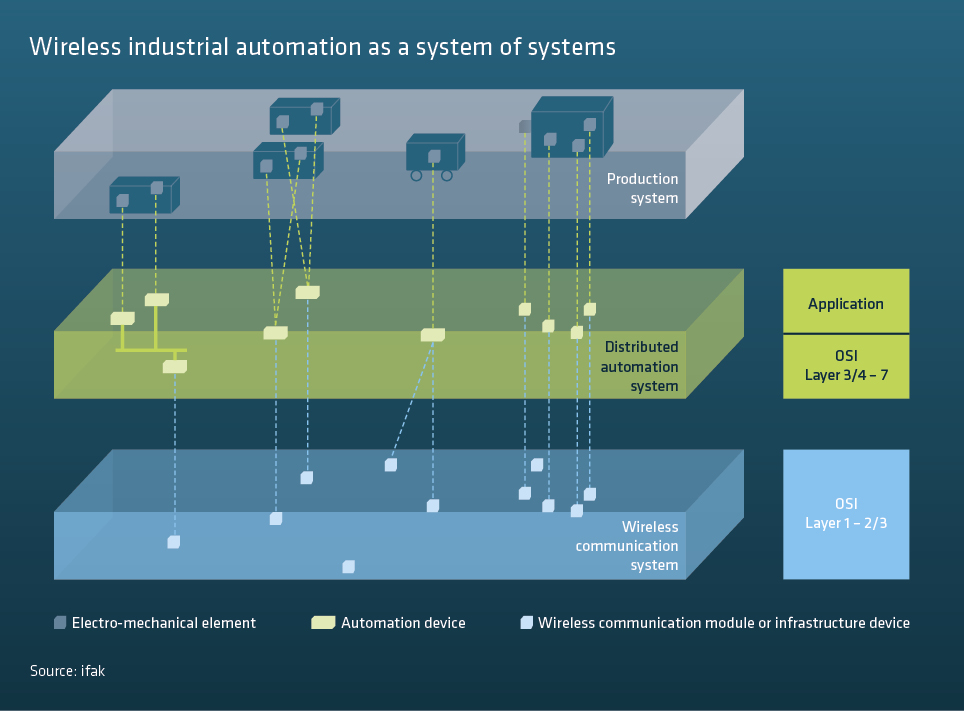

When interfacing the testing system and the system under test, the overall wireless industrial automation system has to be understood. It usually consists of three parts: the production system, the distributed automation system and the wireless communication system. These systems have a complex interdependency which has to be taken into account when preparing performance tests.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe understanding of the term “Performance testing” differs, although it is commonly used. This white paper explains performance testing from an industrial application’s point of view revealing its unique meaning in this field. The universal approach developed in this white paper is relevant to both suppliers, who seek to state reliable information on their solutions, and to end users, who seek to invest in a suitable solution. It helps both parties to discuss the characteristics of a given communication solution properly by consolidating their understanding. Moreover, the universal approach cannot only be applied to 5G systems, but also to hybrid networks for example consisting of a legacy industrial Ethernet network and a 5G system. Finally, the ideas presented in this paper allow a preview of what will be relevant when discussing the certification of industrial 5G devices.

Do you want to learn more about this future-oriented topic? Please download or share the 5G-ACIA white paper as a PDF file.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information